>Hvac drawings: including system diagram, equipment point, pipes floor plan, end drawings, etc;

Equipment ledger: including the nameplate parameters of water chillers, frozen water pump,cooling water pump and cooling tower as well as the time the equipments has been used.

Refrigeration unit: brand, model, refrigerating capacity, sets, COP, design temperature conditions, power;

>frozen water pump, cooling water pump: brand, flow, lift, efficiency, power, the set numbers;

>cooling tower: brand, single water flow, air volume and temperature conditions, the set numbers

Equipment control mode, whether the control system is included, whether the equipment has frequency conversion operation; Whether the system includes an electric valve (control mode);

The type of cold building, the operation month of the refrigeration system, the daily operation time of each month, and the corresponding load rate of each month;

Which refrigeration units are opened each month, and how many refrigerated water pumps, cooling water pumps and cooling towers are opened accordingly; Monthly freezing water temperature setting instructions (such as 7 degrees water supply throughout the year); Record the cooling return water temperature in each month of the year (for example, the return water temperature in July is 32 degrees, and how much degrees of return water temperature in other months);

End form (fan coil, AHU, etc.), terminal control form (BA or manually open)

>Refrigeration room meter reading data: including chiller operating parameters, refrigeration water pump, cooling water pump, cooling tower operating parameters;

>Monthly, itemized power consumption of air conditioning system; System accumulated cooling capacity data (if available)

>The existing problem of refrigeration syste, maintenance and replacement list, etc;

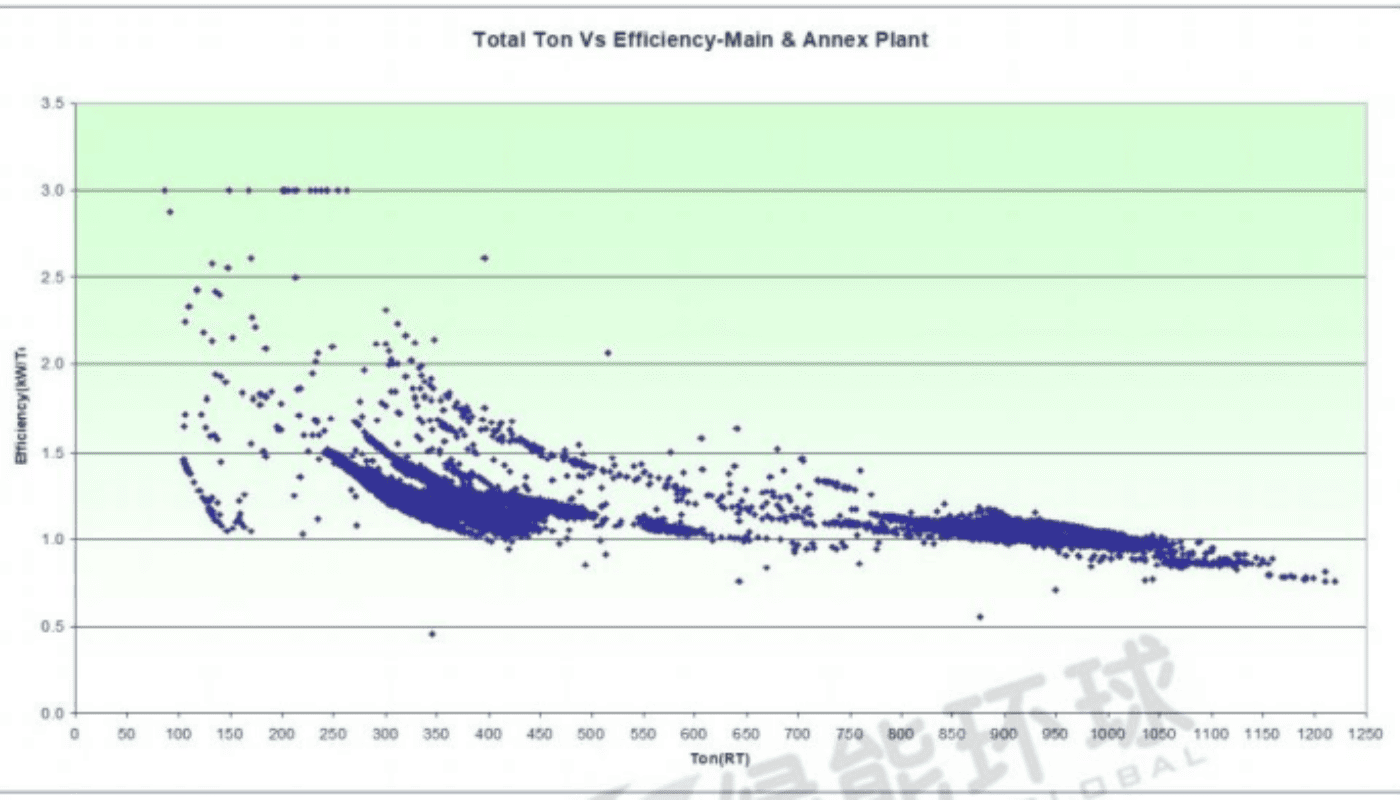

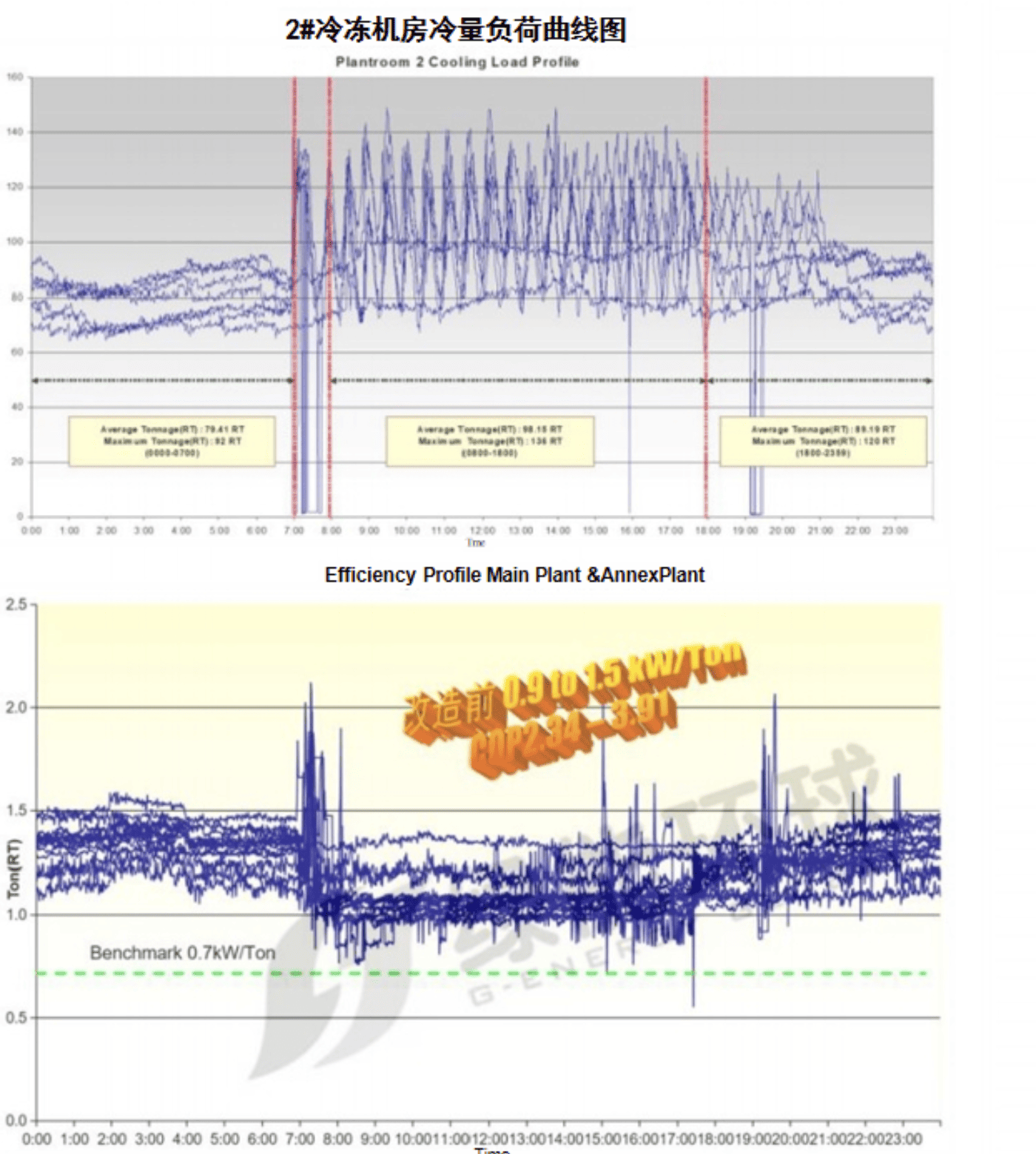

>Energy consumption ratio, change trend, moving average

>Equipment design energy efficiency, preliminary assessment of existing energy efficiency

>Preliminary accessment of system energy efficiency

>Preliminary judgement of system problems

>Site survey for key points

Field detection diagnosis and testing

>Chilled water flwo of chiller, the temperature of supply&retrun chilled water on the host side, the temperature of supply&retrun cooling water on the host side, host operating power

>Pump flow and head, pump running power

>Outdoor temperature and humidity, cooling tower fan running power

>Estimate EER of refrigeration station and calculate the possible EER after renovation.

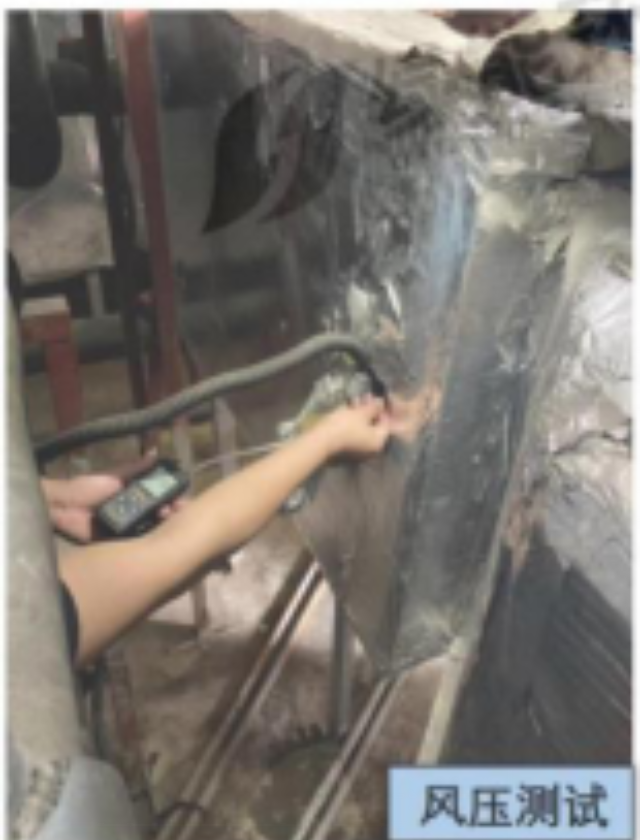

Test of wind pressure

Test of flow

Test of wind quantity

Test of water temperature

① Load rate analysis aren’t be considered when choosing the type of fixed frequency chiller, chiller group stay at lower load status for long time.

② Variable frequency chiller can’t convert in the actual operation process or the logic of variable frequency is confused, cause the problem of valve.

③ Lack of Maintenance, the approaching temperature of evapotor and condensor is too high and lack of refrigerant, etc.

① The resistance of the system pipe network is too large, and the actual operating point of the pump is low.

② The pump is not debugged before it is put into operation, and the running point of the pump is skewed to the right, deviating from the efficient area;

③ The check valve of the parallel water pump set is damaged, resulting in insufficient water flow of the chiller. Therefore, it is necessary for one chiller to operate with multiple pumps.

④ The pump motor cannot be converted normally, and the system runs in the condition of large flow and small temperature difference.

① The water distribution of the cooling tower is uneven, the cooling tower packing is damaged, and the cooling tower motor belt is loose.

② The design of cooling tower did not consider the problem of site layout, resulting in insufficient cooling space

③ The cooling tower fan cannot be normally converted, the operation strategy is unreasonable, there is no intelligent group control system, and the operation of the system equipment is not matched and coordinated.