Background Overview

With the development of human economy, central air conditioning is used more and more widely. Central air conditioning not only satisfies human life and production, but also brings huge energy consumption. In the early design of the central air conditioning system configuration is too large, the degree of intelligence is low, the design of the central air conditioning system only from the point of view of use, rarely from the perspective of energy conservation, this situation undoubtedly increased the energy consumption of the central air conditioning system. Under the circumstances of increasing tense of energy, "energy conservation and emission reduction" has become the common mission and responsibility of the world.

According to statistics, in the industrial field that needs to use central air-conditioning system to meet the production needs, the energy consumption of central air-conditioning system accounts for 20-30% of the energy consumption of the factory, the energy consumption of central air-conditioning system in the building field accounts for 50-60% of the energy consumption of the entire building, and the energy consumption of the cold source station room accounts for 50-60% of the energy consumption of the entire central air-conditioning system. Therefore, the energy saving of central air conditioning cold and heat source station is of great significance.

Concept

Performance-based Energy Centric Solutions

We proposed solutions based on how the building will operate according to its real world conditions, as opposed to prescriptive -based recommendations to meet broad requirements.

Every building is different and we tailor it through simulation and analysis, we are able to understand how the building will perform based on its specific design, location, climate, and operational conditions.

Conceptualization

Calculation

Simulation

Materialization

Verification

Digitization

EER&Goal

Energy efficiency evaluation index of refrigeration room: EER of annual operation

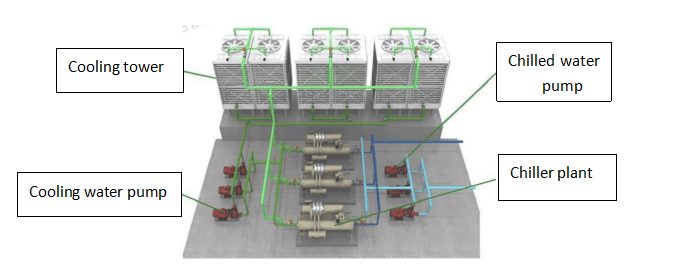

Power consumption equipment includes water chillers, chilled water pump, cooling pump and cooling tower.

Refrigerating room EER (Annual average)= Annual Total cooling capacity (kWhc)/ Annual Total Electricity (kWhe)

High efficiency refrigeration room energy efficiency target:

Annual average refrigeration room system EER (Average annual comprehensive energy efficiency):

EER reach the 5.0 or better (means less than 0.7 kW/RT)